You never know until you try...

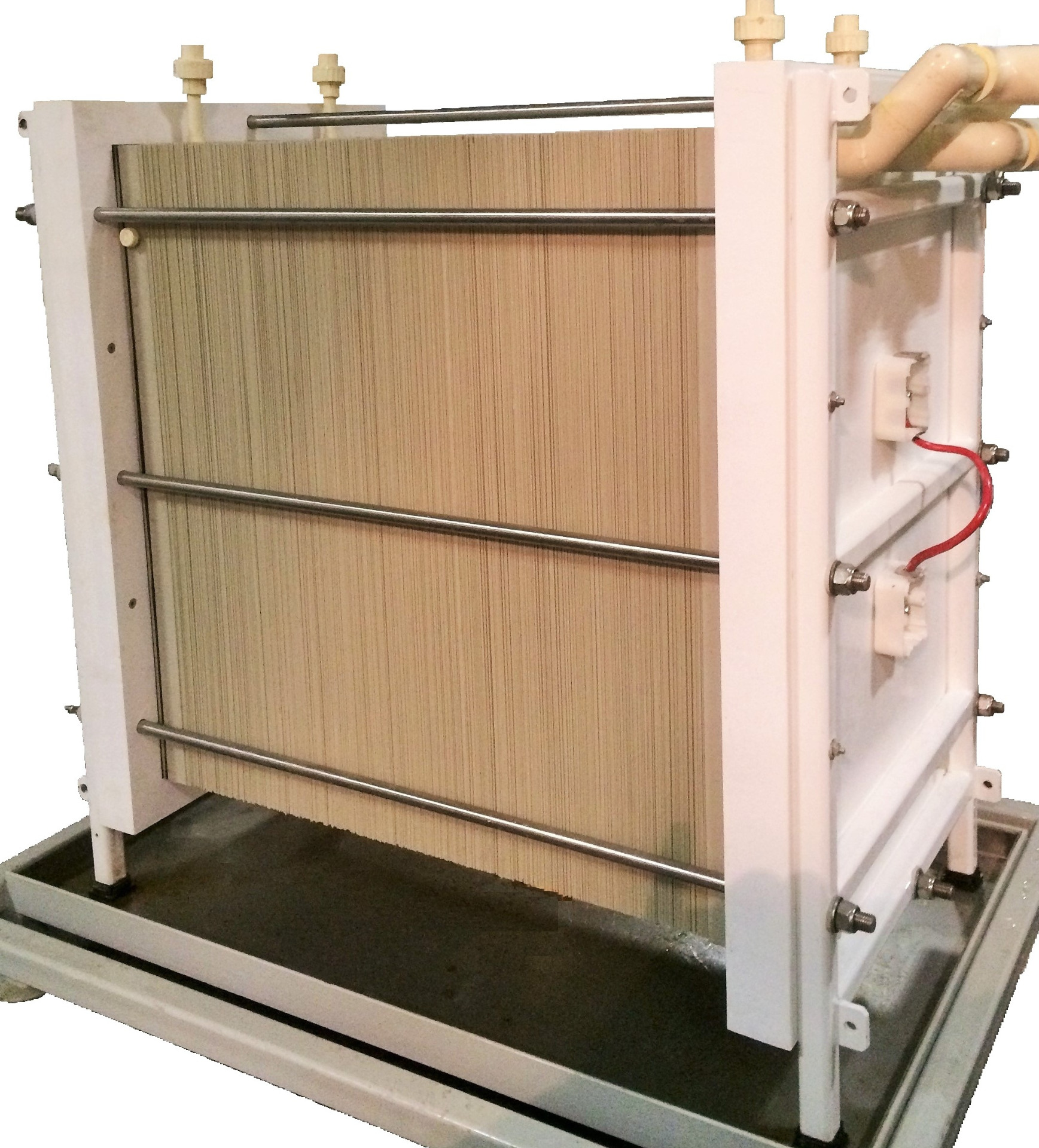

Electromembrane Modules

• We design, manufacture and deliver electrodialysis modules with unique characteristics, various capacity and for various applications.

• Each type of electromembrane module can be designed with 2-, 3- or 4- independent flow channels depending on application.

• Our stacks are used for process demonstration, research & development of new applications, experimental lab and pilot testing as well as for industrial manufacturing.

• Stacks have EU origin and are delivered along with necessary documentation, certification, warranty and post-warranty service, technical support and spare parts.

Main technological features and advantages

• OPERATION AT HIGH TEMPERATURE. Our stacks can process solutions in wide range of temperature from +10°C up to +70°C. Traditional electrodialysis systems operate at temperature in range 15-40°C;

• PROCESSING OF FEED WITH HIGH DRY MATTER. Demineralization of viscous solutions with 40-45%TS directly without water dilution. Traditional electrodialysis systems needs in dilution of raw materials up to 18-20% TS;

• LOW INLET PRESSURE. Low operating pressures of feed solutions 0,5–1,0 bar in one stage. In most of electrodialysis systems operation pressure can reach to 3,5-4 bar;

• NO INTERNAL LEAKING. Due to our unique spacer and stack design we do not have physical internal leakages between product and concentrate chambers. In most of electrodialysis systems the loss of products have substantial amount, and this is the real problem;

• NO EXTERNAL LEAKING. No external smudges and "sweating" on the surface of membrane stacks (stacks with "dry surface"). In most of electrodialysis modules external surface of membrane stacks usually wet. As a result, under the modules arises spills of solutions, and in some cases on the surface even mold is formed;

• DIRECT COUNTER-CURRENT OF FLOWS. Direct ("true") counter-current flows of the working solutions inside the membrane stack allows higher level efficiency of demineralization and optimal conditions for membranes.

• UP TO 4 STACKS IN SERIES. Possibility to install 2, 3 and 4 modules in the technological production line in series, without intermediate tanks and additional pumps to provide one-flow ("single-pass") deep demineralization scheme.

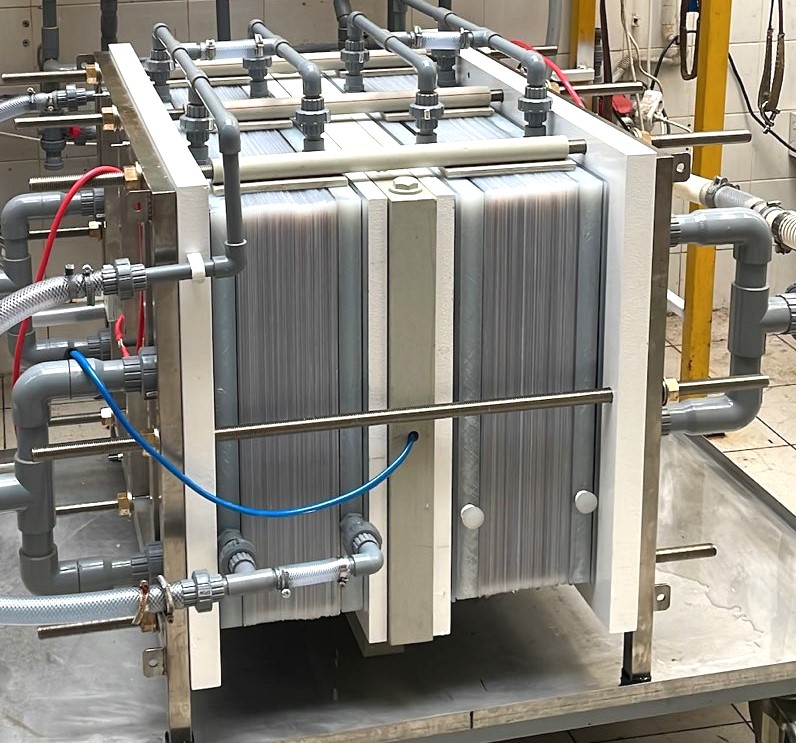

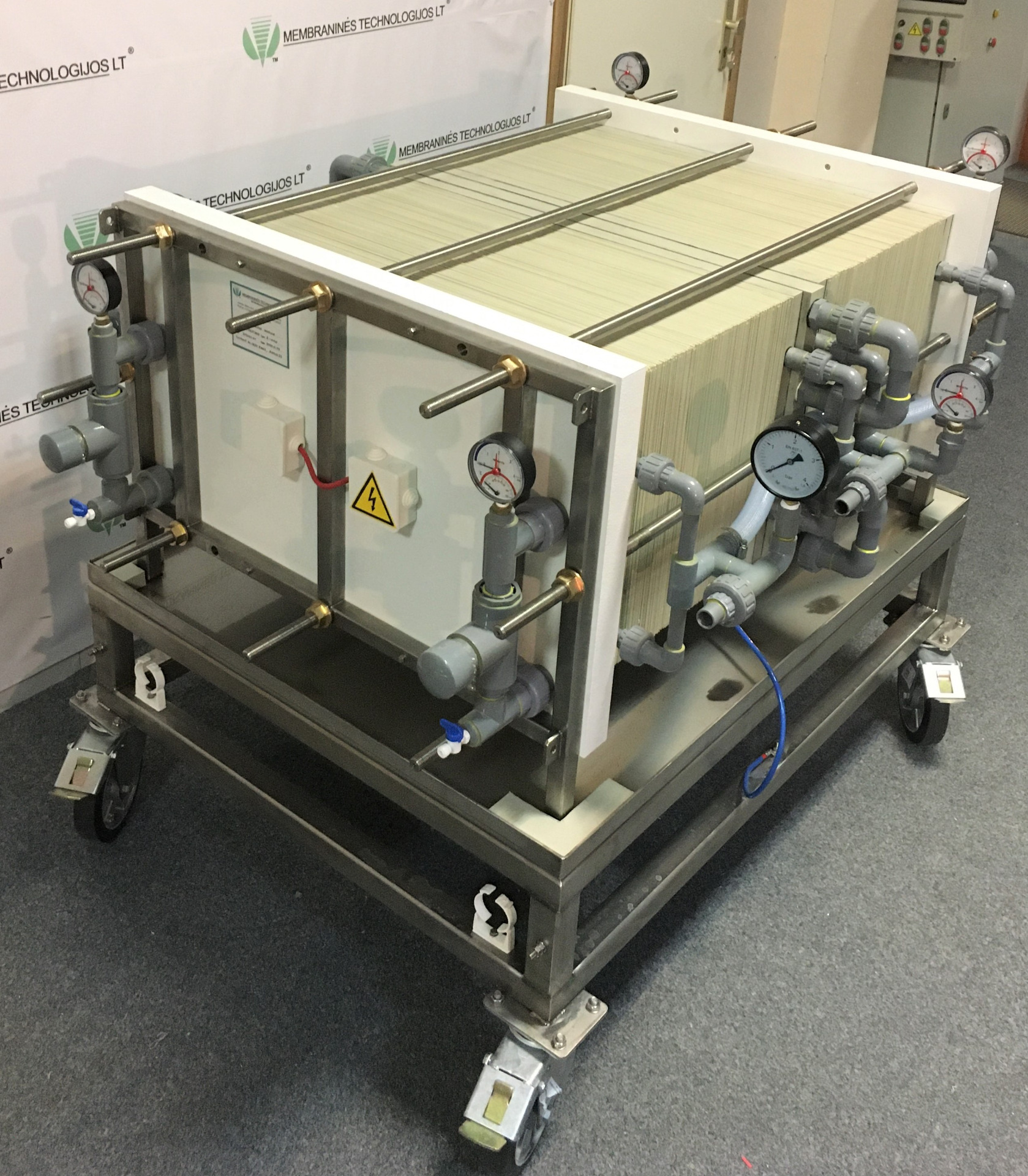

Industrial Electromembrane Plants

• Apart from delivery single stacks as a separate products, we also supply complete electrodialysis plants on the "turn-key" basis.

• Our equipment has been installed at more than 100 enterprises and plants in various industries of the EU, CIS, Middle East and Central Asia, South America - metallurgical, energy, pharmaceutical, chemical, food, hydrometallurgy and many other.

• Some pictures of typical ED Plants on the real industrial projects are shown below.

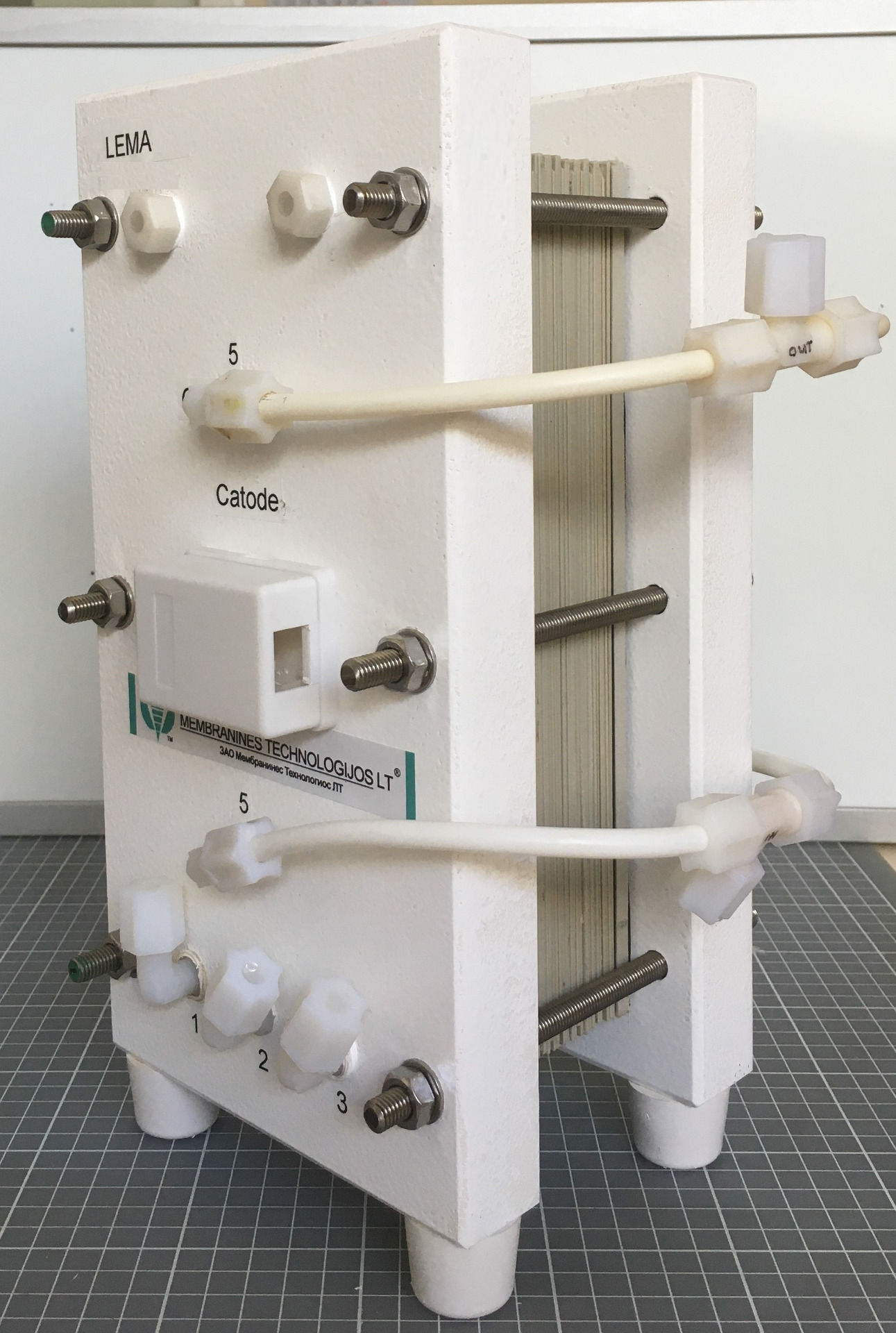

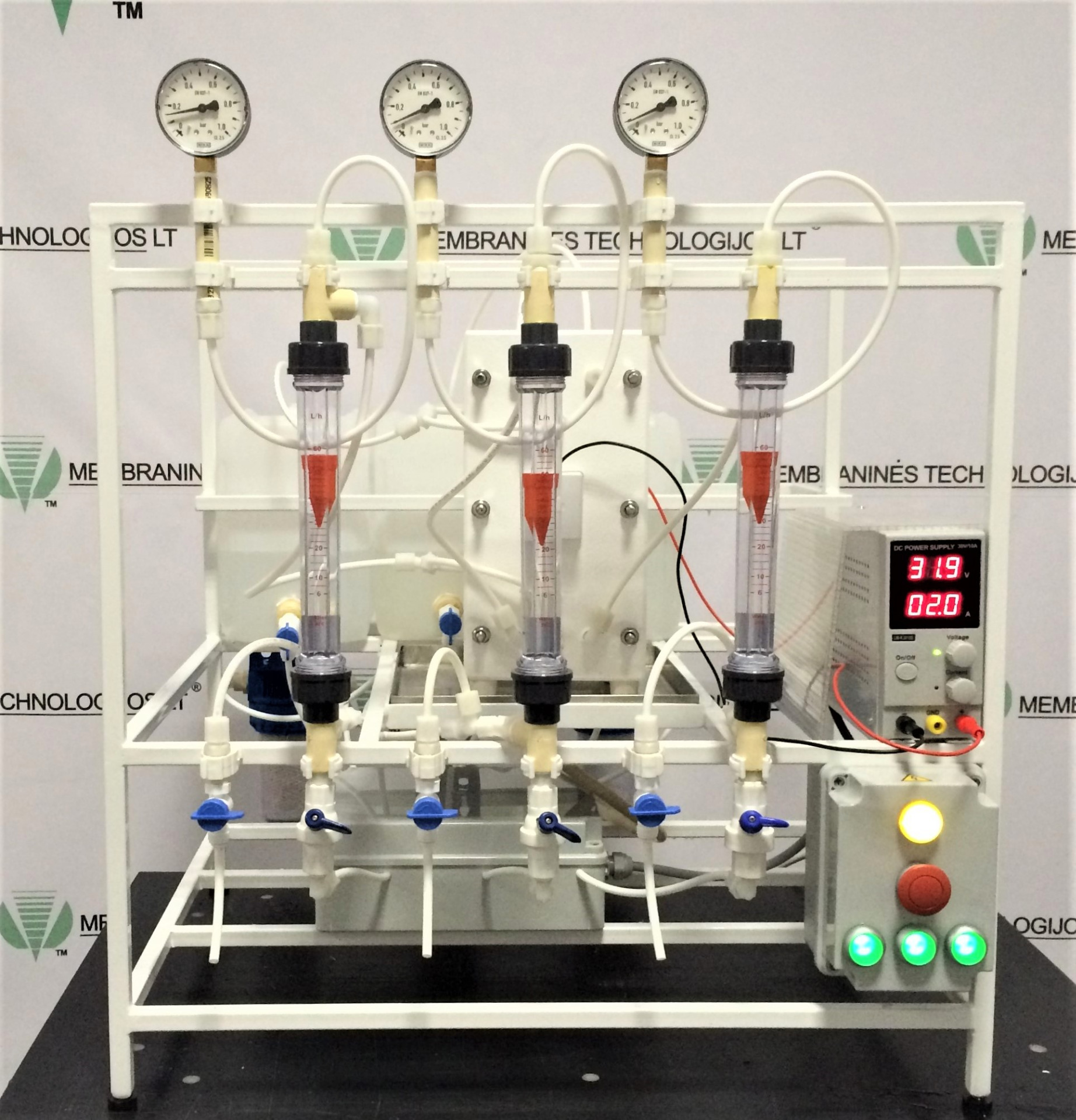

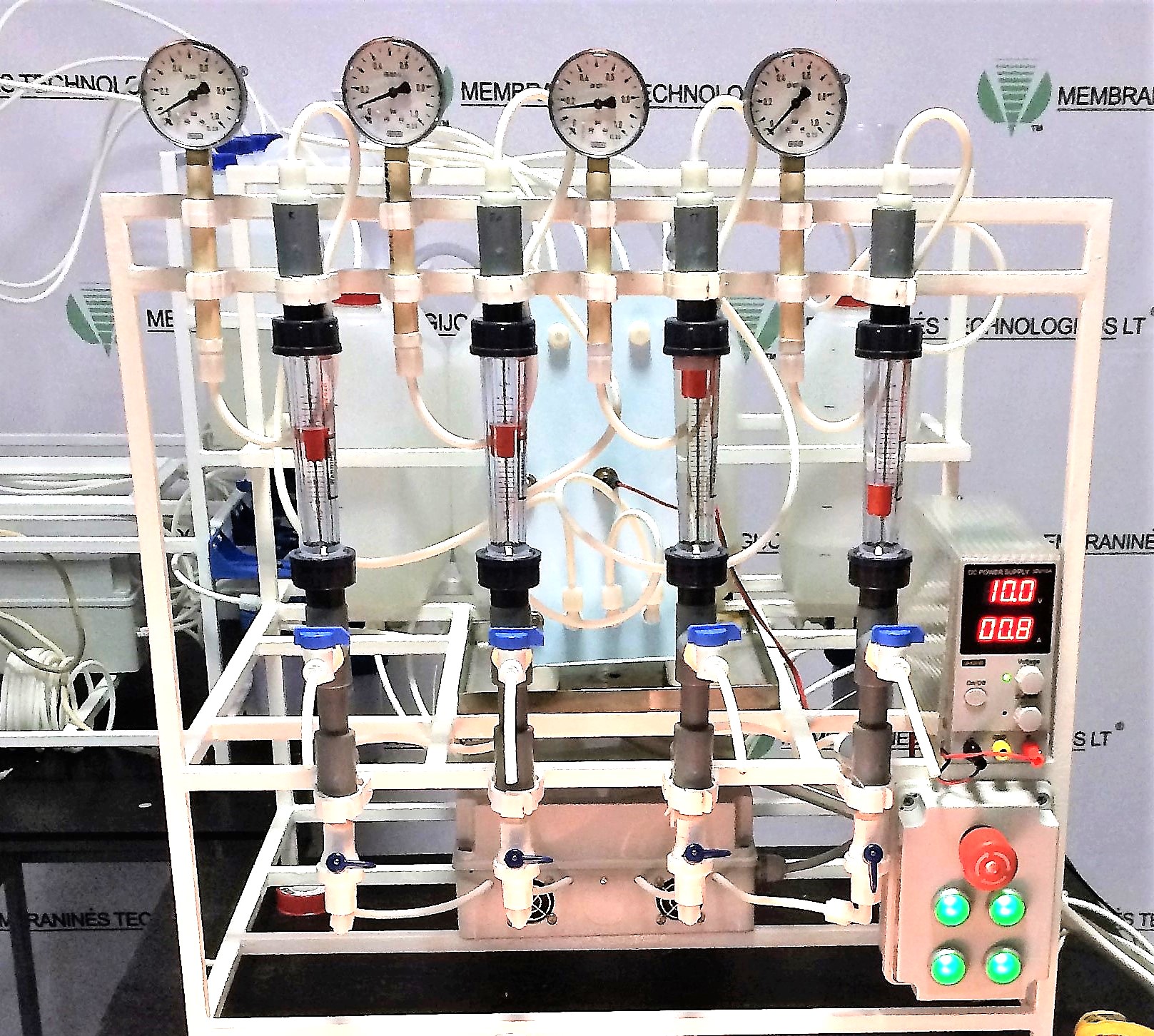

Lab-scale and pilot electrodialysis Plants

Separate product line is Lab-scale and Pilot Electrodialysis modules LEMA series, and Plants UOLEMU series operated on electrodialysis principle – are unique special products which are designed for conducting laboratorial and experimental works for research the processes of demineralization, softening, concentration of solutions, new substances synthesis, obtaining deeply desalinated water, removal of an inorganic components in water solutes of organic matters, for waste water treatment; for whey desalination and removal of excess lactic acid and other acid from all types of milk products; removal of unwanted inorganic admixtures in technological solutes; alkali extraction from organic solutes, alkali separation from collector regenerative wastewater and other solutes etc. At the same time, the lab-scale equipment is capable of processing viscous and highly concentrated solutions, as well as solutions with an elevated temperature.ED modules LEMA series manufacturing are in different types of membrane stacks: for classical electrodialysis processes LEMA-ED/EDR, bipolar modules LEMA-BM in tree options of membrane stacks assemby and for diffusion-dialysis extraxtion modules LEMA-DDE of acid and/or alcali.

Labeled Plants UOLEMU can include 1-, 2-, 3- or more number of ED modules LEMA, depending from Client`s option.

Just write to us and we agreed delivery Specification in accordance with your needs!